Project Profile

Centro Richero Fiat, in early 2001, was the first automobile manufacturer (and second user overall, after Delphi in 1998) to purchase Measurement Technology Northwest’s STAN Seat Test manikin system. For 10+ years, our STAN’s hot, sweaty backside was a fixture in the Fiat testing lab ably and accurately measuring the thermal comfort characteristics of automobile seats and seat materials. But when a lab accident in 2011 led to STAN’s untimely and premature demise, Fiat’s researchers contacted MTNW to explore the pros and cons of repair vs purchase of a new STAN. After MTNW engineers determined that damage to Fiat’s old STAN was extensive, to the point that repairing the manikin was not an option, the conversation quickly shifted to reviewing the capabilities of our current STAN manikin system.

What a difference 10 years makes!

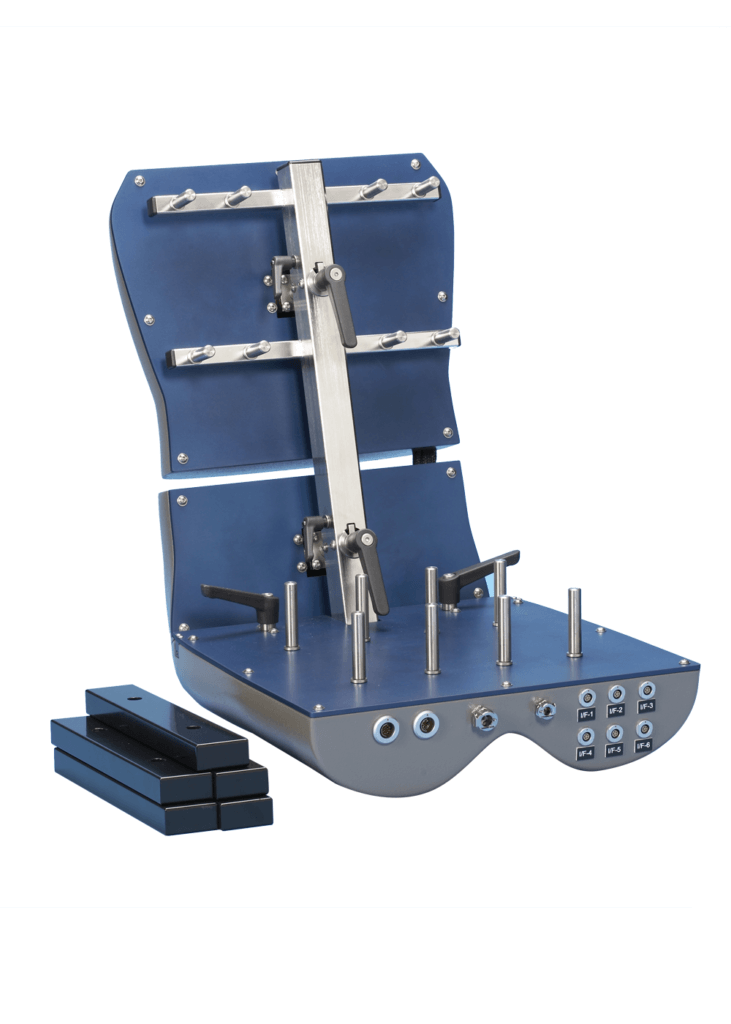

MTNW’s current STAN sweating thermal manikin has evolved to include a wide range of impressive capabilities, including articulation of the lumbar seat-back region, an integrated cooling capability for testing heated seats, an integrated seat compression/weighting system, and a body contour design that is fully compatible with existing industry standards and automotive seat positioning methods.

STAN is now the one comprehensive tool that automotive testing labs need for testing passive seats, heated seats, and cooled/ventilated seats! To accomplish this remarkable feat, 11 independently heated thermal zones, including 6 porous metal sweating zones, have been incorporated into STAN’s back and buttocks regions. All zones are fit with heaters to simulate human metabolic heat output rates while high accuracy sensors in each zone measure and monitor real-time temperatures.

The sweating zones fitted into the manikin’s skin surface are supplied with fluid by a micro-metering pump and valving system. Separate flowrates can be selected for each of the sweating zones. Each thermal zone on STAN is also equipped with an integrated cooling function that operates in a way similar to blood flow in a human. This internal circulation system carries away excess heat from zones exposed to elevated temperatures, such as with a heated seat.

In addition to maintaining accurate skin temperatures while in-use, STAN’s innovative cooling system allows the energy transfer rates from a heated seat to be measured. Advanced STAN technology lets researchers characterize the insulative and moisture exchange values of passive, ventilated, and heated seats. Properties such as thermal resistance, evaporation limit, maximum heating power, and transient heatup time can be accurately evaluated. By providing benchmarking capability for functional seat specifications, STAN offers researchers a path toward standardization and more comparative seat testing results.

In addition to the new STAN thermal manikin being built for the Fiat testing laboratory in Italy, STAN systems are also operating in Germany, Japan, and the USA.

Measurement Technology NW manufactures a wide range of precision instruments for measuring and evaluating the thermal comfort of textiles, garments, and environments such as automobile, truck, and aircraft interiors. Our systems support all major ASTM, ISO, and ENV textile testing standards. To learn more, contact us at 206-634-1308, or send an email inquiry to [email protected].