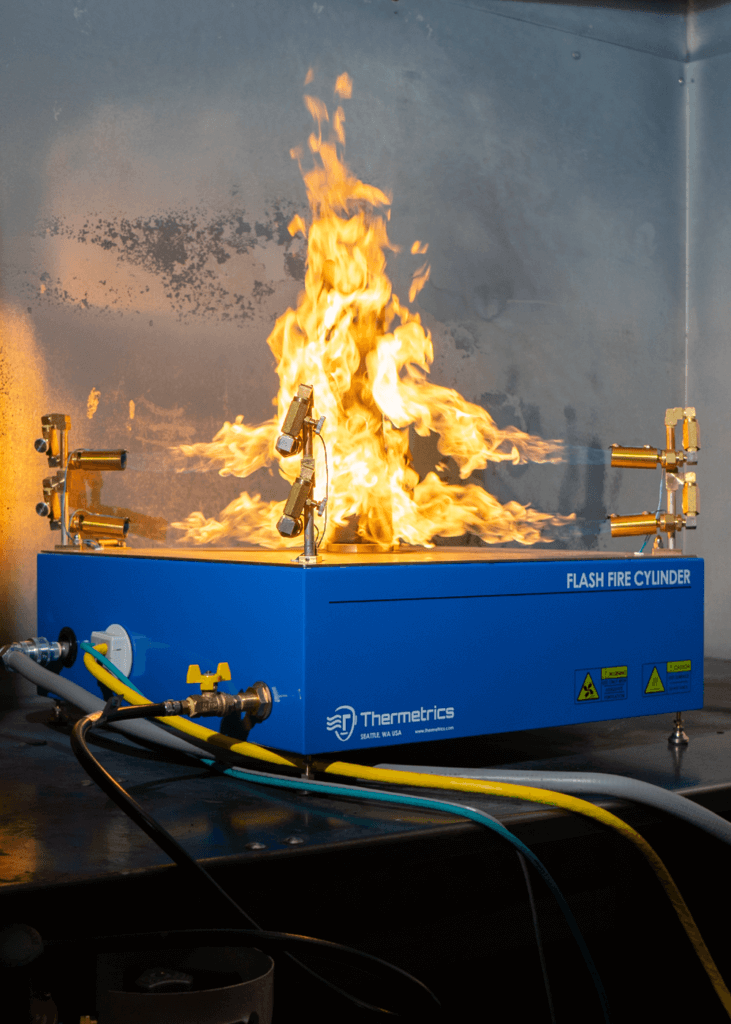

In what started as a rough sketch on a flipchart during a brainstorming session, the Flash Fire Cylinder (FFC) has evolved into an highly repeatable, closer-to-reality bench-scale tool for testing thermal performance of textiles.

PBI president Bill Lawson recently narrated the first in a series of videos on how the FFC is helping achieve their goal of providing lightweight, comfortable PPE for end-users. The first video covers the need and evolution of identifying a closer-to-reality way to test the materials for PPE. The second video highlights some key features of the FFC.

“The closer-to-reality testing the FFC affords is a huge benefit to garment makers, helping them better-understand how their garments will perform in the field.” – William Lawson, President of PBI

About the Flash Fire Cylinder

With its cylindrical design, 15 embedded sensors, and sample holder rings creating a quarter-inch air-gap, the FFC provides a much closer approximation to the human body—the actual end-use case. Benefits of the device are many, including:

- A huge cost-savings with the ability to test materials at a bench scale before going to full-scale manikin tests

- Compact for use in existing lab environments

- Easy sample prep and installation for highly repeatable test conditions

- Integrated, robust safety precautions for test operators, including an external emergency-stop interface

- Ability to see the effects of dimensional changes in the material under very controlled conditions

Be on the lookout for more videos in this series from PBI Performance Products, and contact Thermetrics to learn how the FFC can support your org’s materials testing needs.