Dry rate testing with superior accuracy

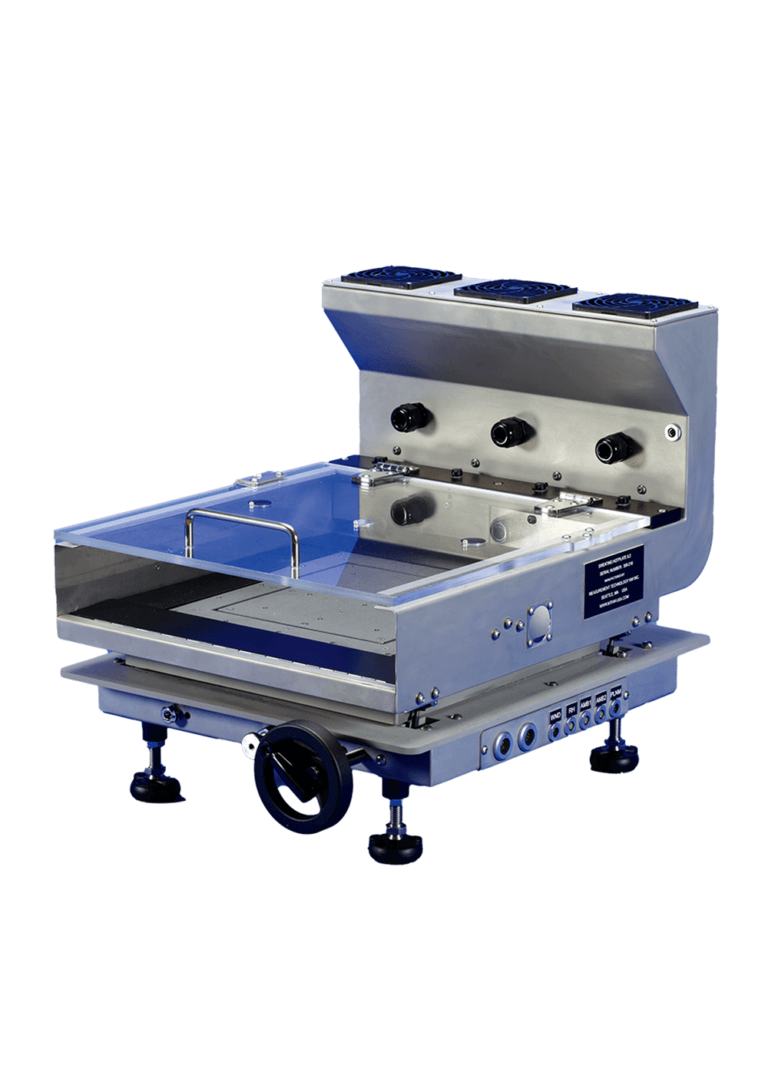

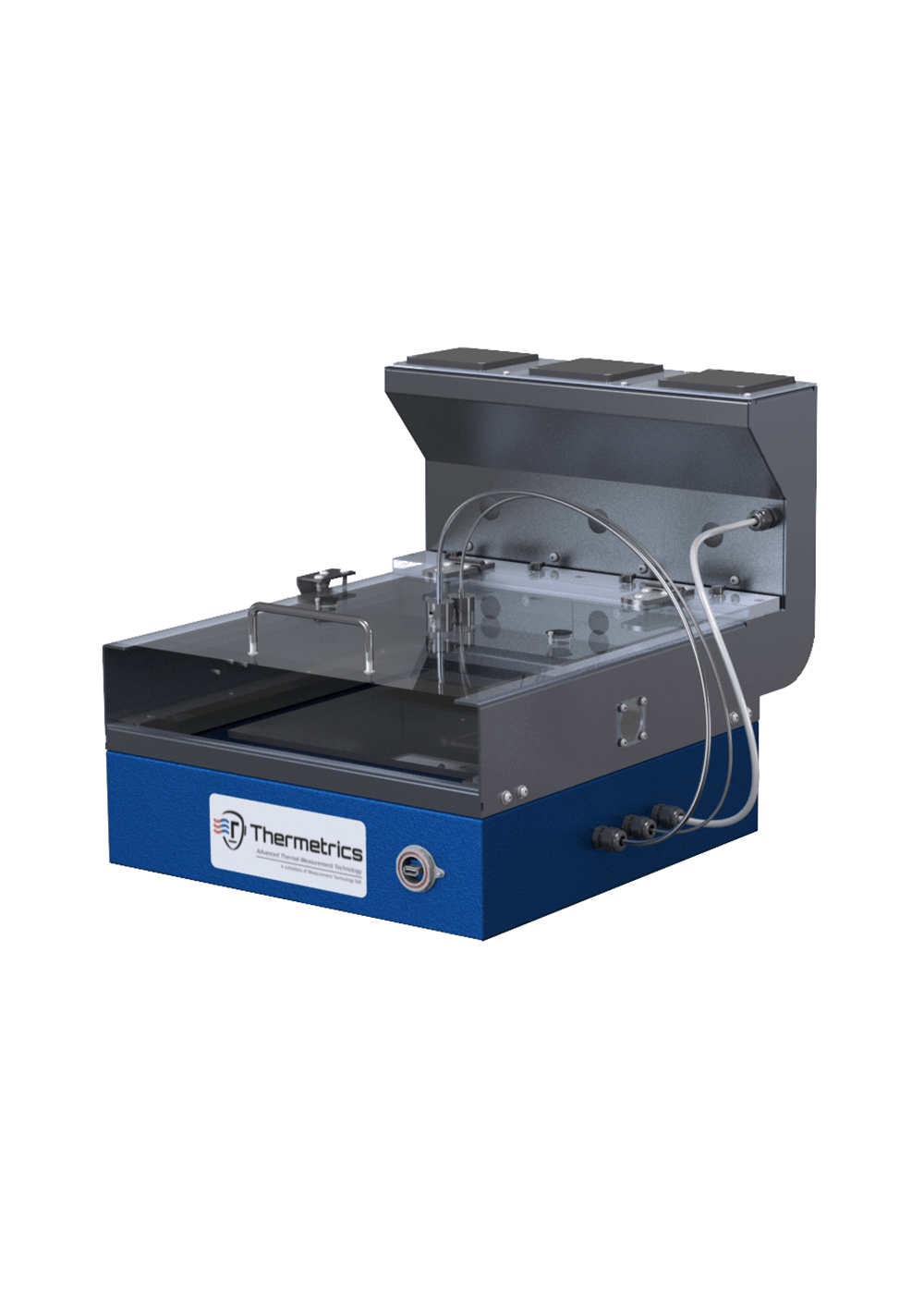

Thermetrics Drying Rate Tester 201 (DRT201) determines the drying rate of a fabric based on the evaporative rate that occurs when a predetermined amount of water is absorbed into a fabric that is placed upon a heated plate and then dried with constant controlled air flow.

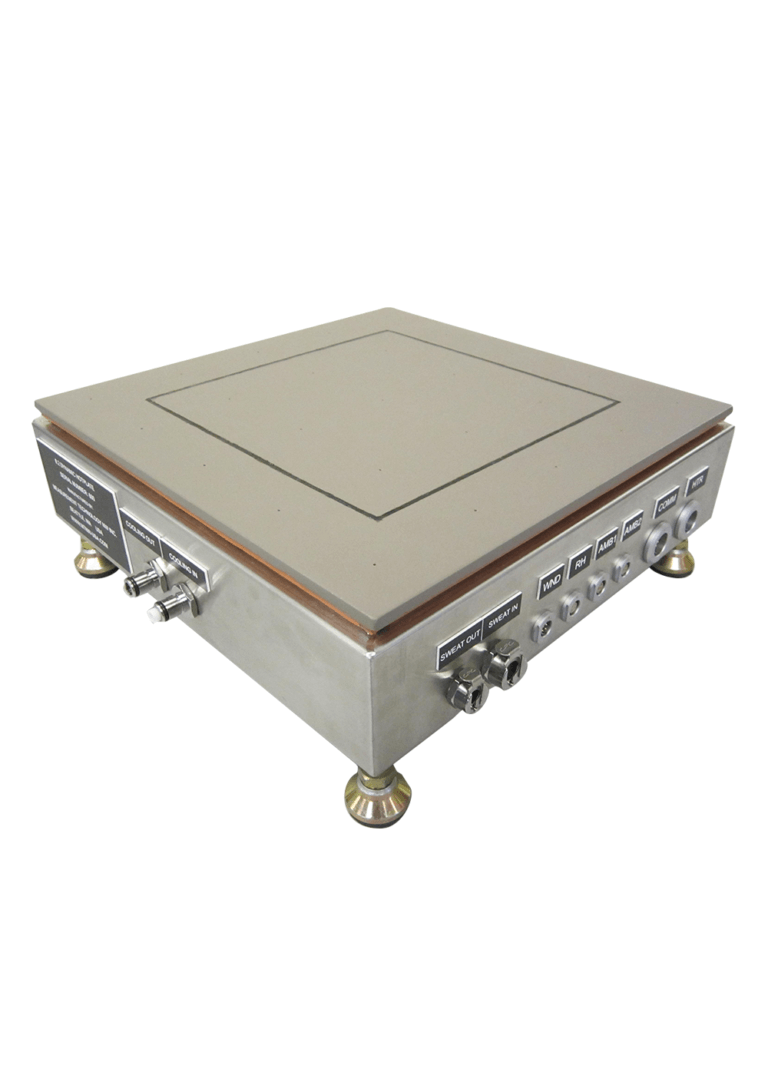

- Superior temperature uniformity. We use electronics-grade copper for the heated plate. (add this bullet to top of highlight and benefits in spec sheet as well - use original bullet from webpage - not this modified version.)

- Fluid delivery precision. Computerized syringe pump allows for consistent, repeatable delivery.

- Airflow control. The precision-engineered airflow geometry of the DRT-201, coupled with our precise tuning ability, provides consistent results over a range of ambient lab conditions