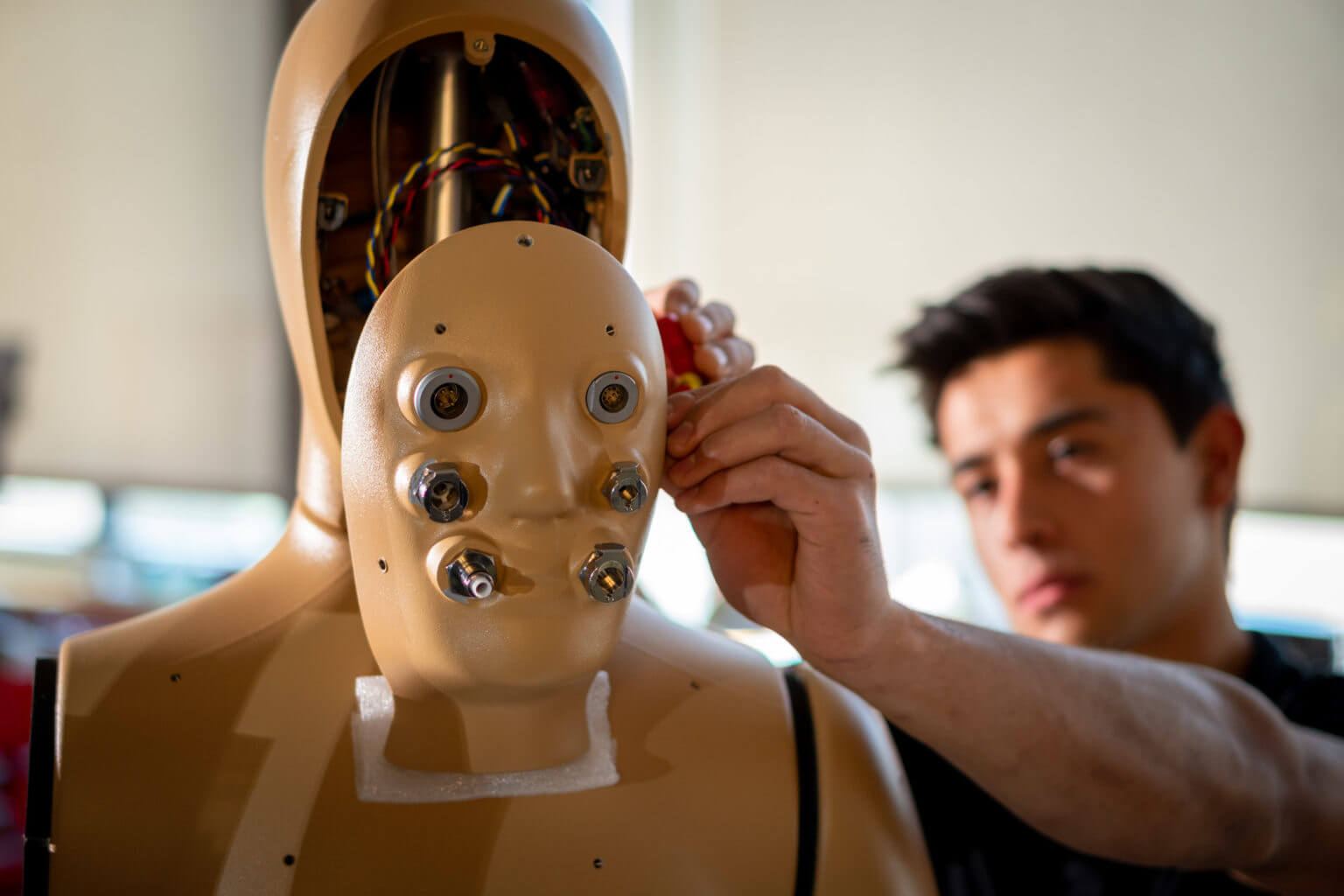

Thermetrics’ advanced Newton 26-zone sweating thermal manikin, STAN seat test manikin, and the HVAC Automotive manikin are available for rent/hire. These complete turn-key systems include manikin, laptop PC, ThermDAC control software, startup and training at the client facility, as well as ongoing technical support.

Thermetrics has prepared these rental systems because there are times when a manikin rental makes more sense than a purchase. For example, rental systems are perfect for short-term research projects of 1-4 months in duration. Rentals can also be an inexpensive way to evaluate the capabilities of a manikin and build a strong business rationale for future capital spending. And if your testing needs are immediate, rentals can be timed to help start or keep research projects moving forward while your new Thermetrics manikin system is being built.

A rental can make sense financially too: Thermetrics applies 20% of your rental fee as a credit towards the purchase of a new Thermetrics manikin or hotplate system – up to 50% of the total cost.

Thermetrics makes it easy. Our team will coordinate the roundtrip shipment (domestic or international), then our engineers will arrive to handle uncrating the equipment, verify that all functions are working properly, and train operators on proper test methodology, software controls, and data analysis. Even after the startup/training session our engineers remain on-call for any questions or issues that might arise.

Call or email Thermetrics today to get more information about our rental program and manikin availability. We look forward to being of service!