Question: What do you get when you combine a high-fidelity human thermal model with a thermal manikin? Answer: You get the most accurate tool available for replicating human thermal response.

Starting in 2009, Thermetrics and ThermoAnalytics (TAI) recognized this potential and the inherent strengths of each company. Given Thermetrics’ focus on designing precision thermal manikins, and ThermoAnalytics’ established thermal solver products and expertise with human thermal physiology, it was only natural—perhaps even inevitable—for the two organizations to work together.

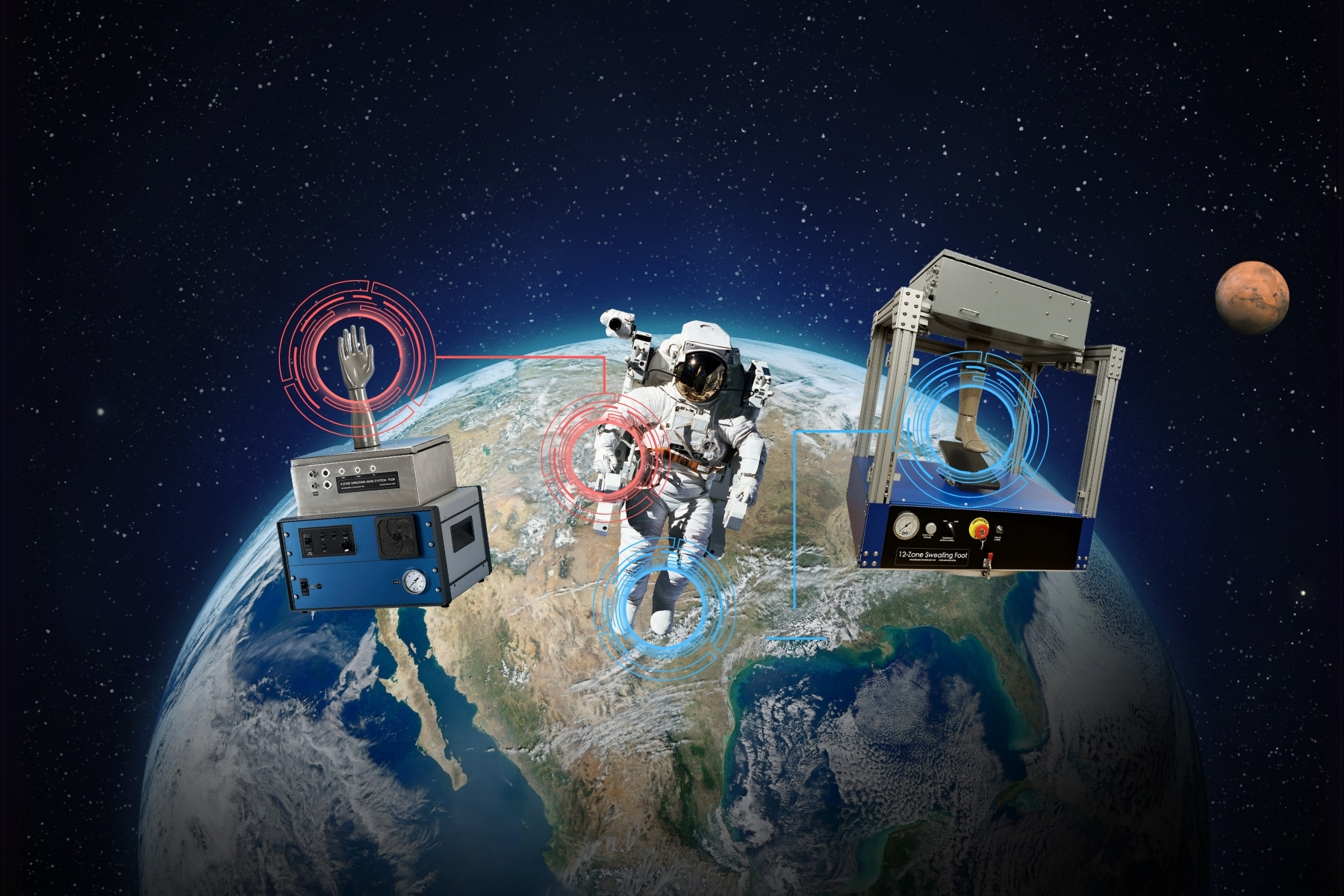

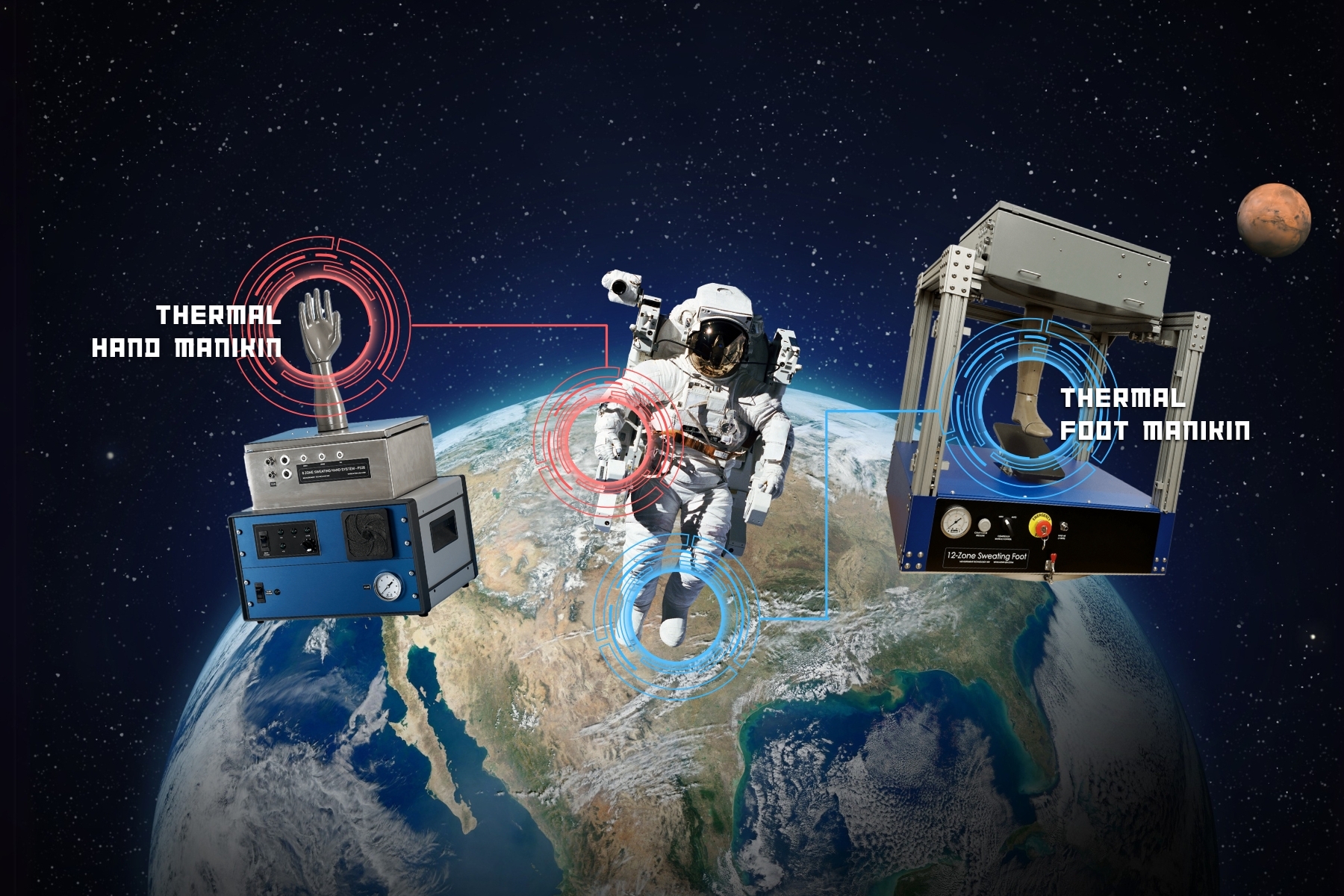

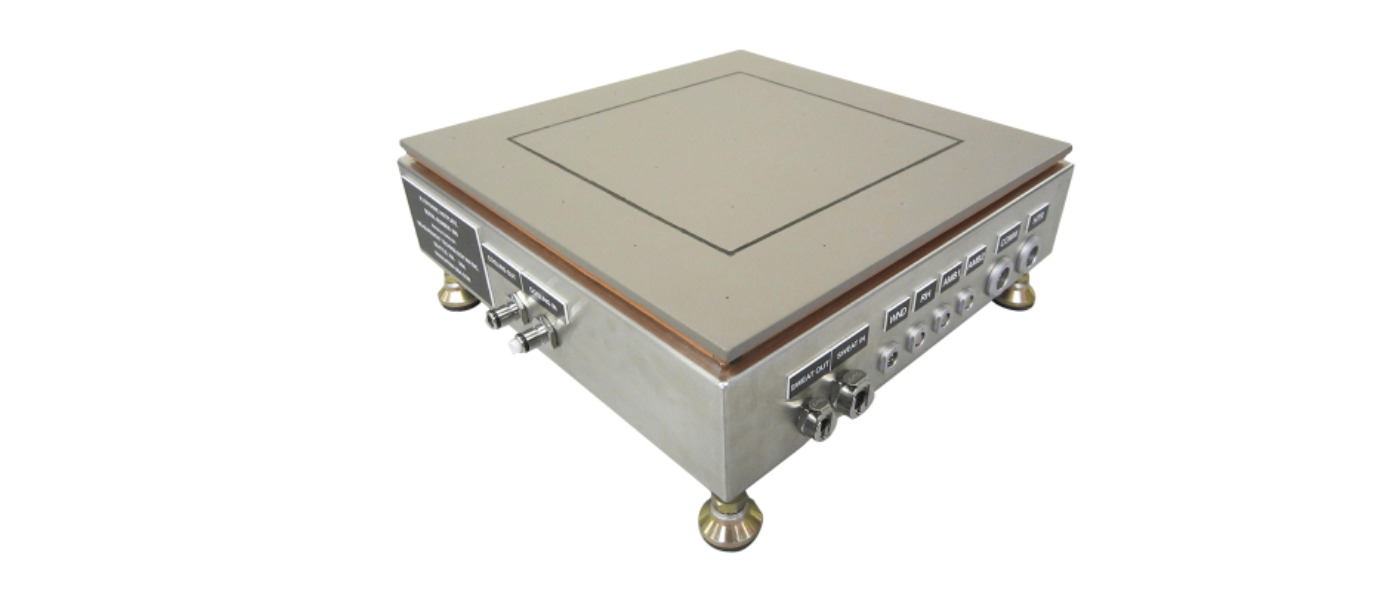

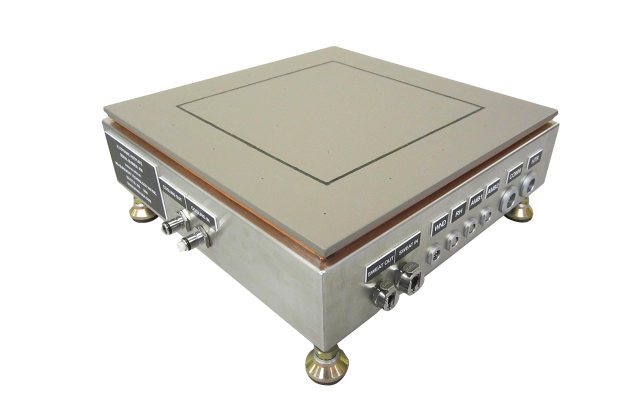

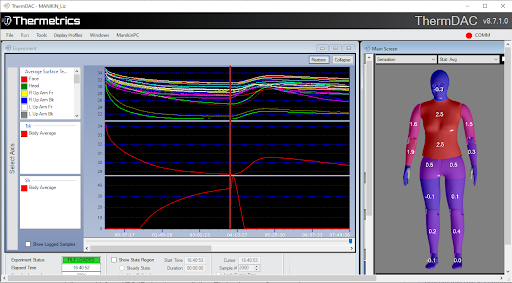

Fifteen years ago, Thermetrics and TAI began joint development to combine TAI’s thermoregulation model TAITherm, with the Newton sweating thermal manikin. The result was ManikinPC manikin software and the world’s first commercially available adaptive manikin in January 2010.

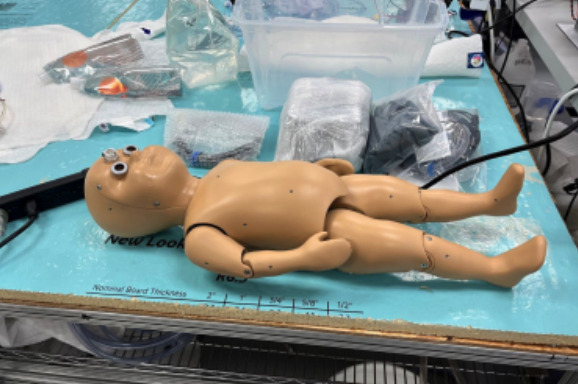

Since that introduction, advances in TAI’s technology have made ManikinPC increasingly more robust, improving the accuracy of human thermal-physiology modeling, solver speed, and user customizations. Joint collaboration has also extended ManikinPC compatibility across the Thermetrics product line to include Liz, child and baby models, and HVAC/ACE sensor manikins.

Founded in 1996, ThermoAnalytics has long specialized in advanced thermal simulation and EO/IR signature prediction. At the core of TAI’s success is TAITherm, the company’s premier thermal simulation package. While it serves as the “brains” behind ManikinPC, TAITherm is a comprehensive computational tool in its own right, enabling engineers to predict, optimize, and validate thermal behavior across complex environments. TAITherm’s applications span a wide spectrum—from automotive thermal management and aerospace signature—to electronics cooling, building performance, and textile thermal behavior.

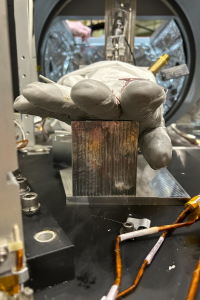

In addition to the collaboration for product development and validation, engineers from both companies often collaborate on-site to support customer testing—Thermetrics from the hardware perspective and TAI on simulation. This offers OEMs a comprehensive team for benchmarking and optimizing existing products.The joint TAI-Thermetrics expertise and tools can also help companies expand virtual design processes to accelerate and test new development. Using both a thermal manikin and TAI’s stellar modeling capabilities, new designs can be accurately tested before ever reaching the human subject testing phase, saving both money and time.

When asked about the working relationship between Thermetrics and ThermoAnalytics, TAI’s VP of Business Development Craig Makens explained, “Our joint clients push the boundaries of what ‘s possible, challenging us to constantly elevate ManikinPC. This collaboration drives innovation, ensuring our technology evolves alongside their most advanced needs.”

If your organization is interested in leveraging world-class human thermal comfort and thermal simulation modeling capabilities to cut down on cost and design time, consider working with ThermoAnalytics. They also happen to be hosting their next Global User Forum in Munich, June 16-17, 2026 where Thermetrics will be presenting. We’d love to see you there!

About the Partner Spotlight. Partner Spotlight is a fun opportunity for us to highlight the capabilities and accomplishments of one of our client-partners each quarter. As an industry-leading manufacturer of thermal manikin systems and other thermal testing equipment, we learn and grow best through partnerships with test labs across the U.S. and worldwide, in addition to collaborations with government and research organizations in need of thermal testing equipment for their innovative research projects. If you can imagine it, Thermetrics can design and build a system to test it!