We’ve all been there. You’re in the air-conditioned car on the way home from the gym or a long practice, and your once hot and sweaty clothes are now cold, clingy, and uncomfortable. Researchers at NC State’s Wilson College of Textiles’ Textile Protection and Comfort Center (TPACC) are making efforts to remedy that discomfort and have made significant strides in doing so with the help of Thermetrics’ hotplate technology.

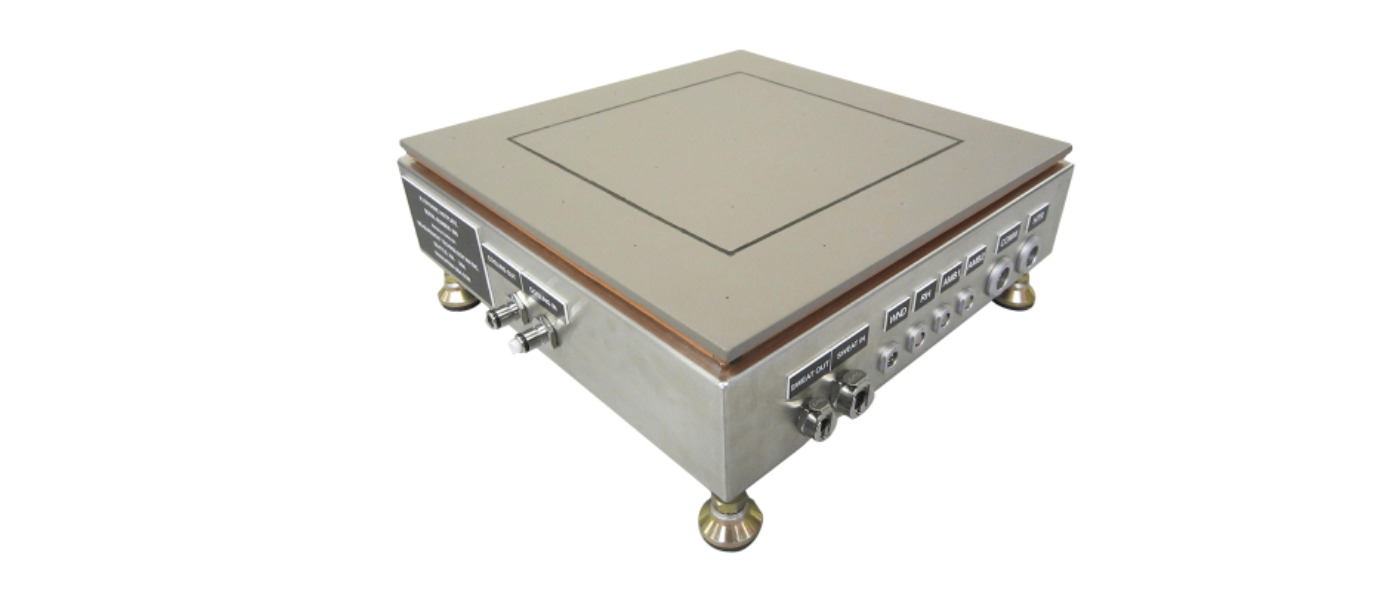

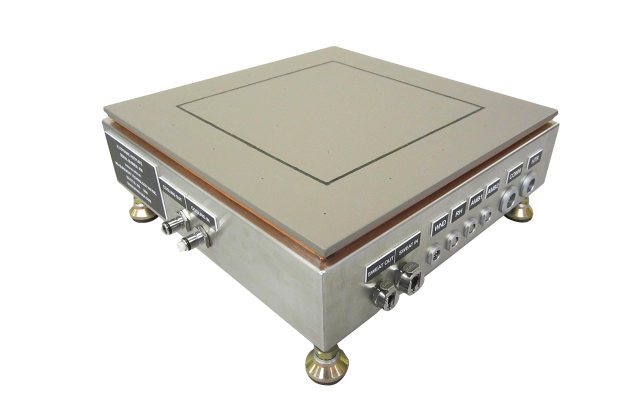

Recently, ASTM International, the globally recognized consensus standards organization, adopted a standardized test created by TPACC, designed to measure a fabric’s evaporative cooling efficiency. It’s likely this test, developed in part with the Sweating Dynamic Hotplate could soon be a go-to testing option for the activewear industry.

While other testing methods are available, they only measure certain factors regarding a product’s cooling capacity, as noted by NC State’s Shawn Deaton and Roger Barker in a journal article from “Medical and Science Technology.”

Want to learn more our Sweating Dynamic Hotplate? Check it out here.