In our earliest days at Thermetrics, our customers helped us understand that a unidimensional approach to product testing only tells you part of the story.

The need for a comprehensive and multi-tiered testing sequence is even more apparent when the products you’re developing are the vital tools of performance and safety for end users like athletes, explorers, and everyday heroes who need top notch protection from extreme hot and cold conditions.

We’ve developed our testing instrument portfolio to cover a wide range of product evaluation needs and test standards. As our product offerings have grown, it’s become more complex to communicate how they relate within a comprehensive product development strategy. Enter our two testing continuum structures for Thermal/Moisture Management and Thermal Protection.

Let’s explore them both.

The Thermal and Moisture Management Testing Continuum

* Want a copy of this image for your reference, or to support discussions with your team? Download this Testing Continuum.

As its name suggests, this testing continuum was created to facilitate optimal garment development, with a particular focus on quantifying heat and/or moisture transfer.

The 5 phases of the Thermal and Moisture Management Testing Continuum are:

- Flat Sample Testing

- Cylinder Testing

- Thermal Manikin Testing

- Physiology & Comfort Model Integration

- End-User Product

![]()

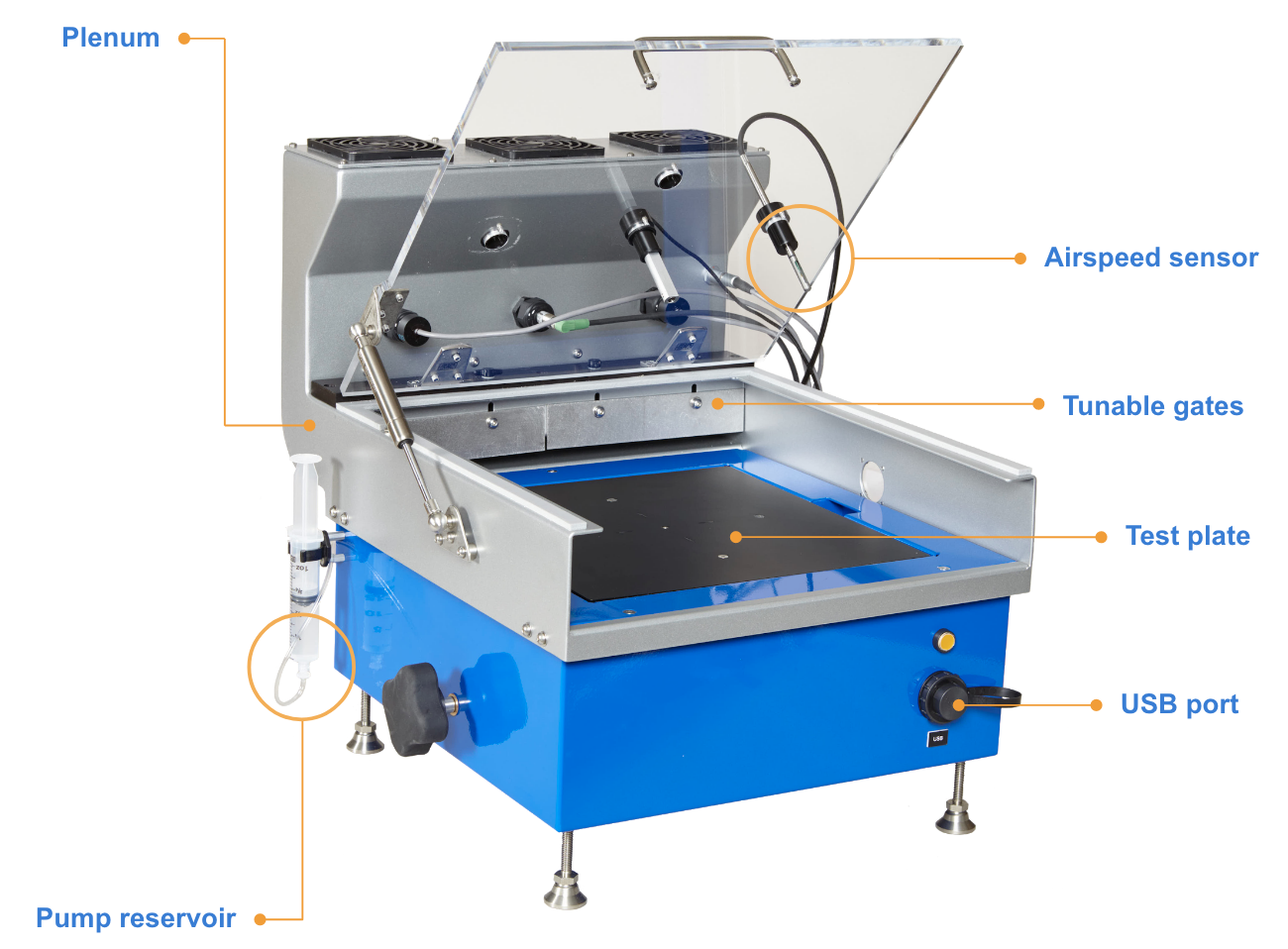

1D. Flat Sample Testing

The basis of system testing starts with understanding the components. This includes accurate, repeatable measurements of thermal resistance (Rct) and vapor permeability (Ret) for single and multi-layer textiles.

![]()

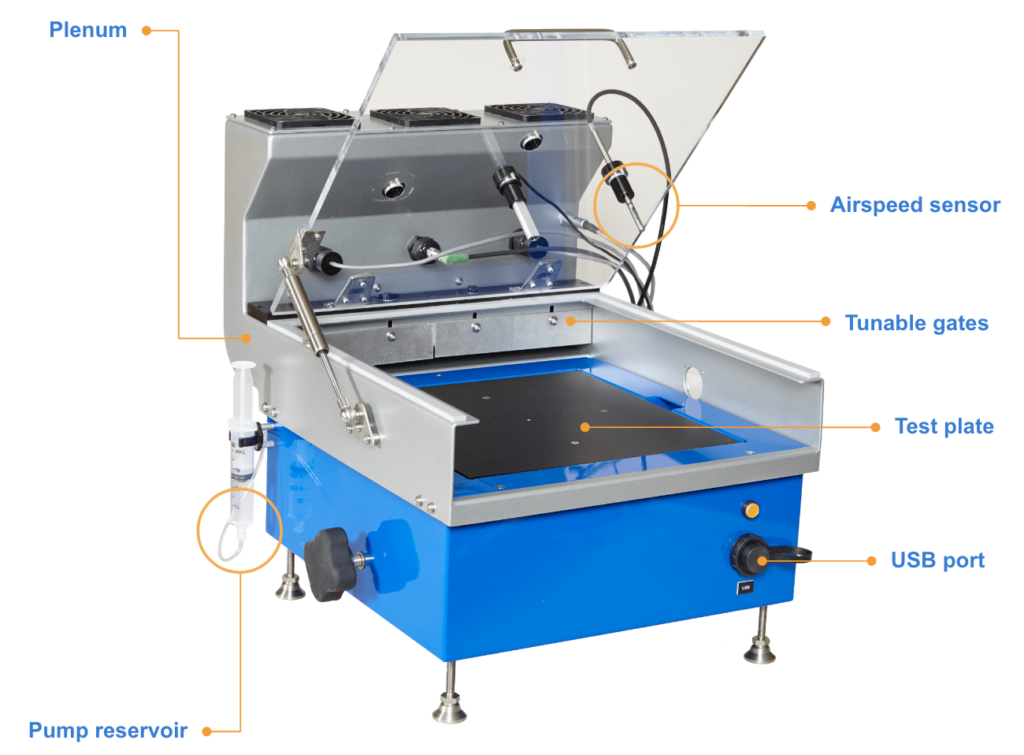

2D. Cylinder Testing

Quantify the impact of undergarment and within-garment air gaps by fitting materials and layered systems on a controlled and repeatable cylinder geometry.

![]()

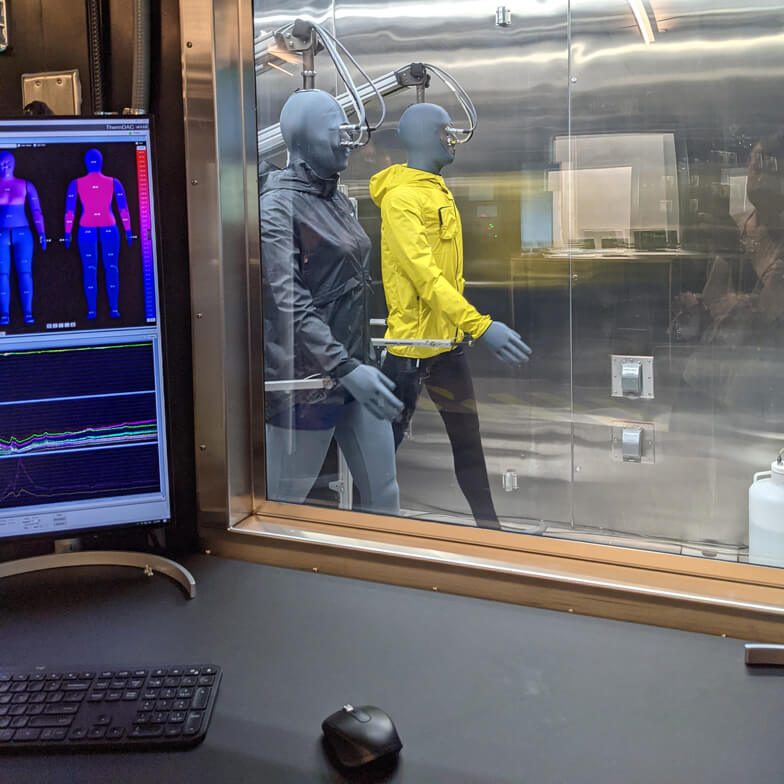

3D. Thermal Manikin Testing

Final products are tested for ultimate thermal and moisture management performance, combining materials, layers, and garment design features in-use on an actual body form with realistic fit.

![]()

4D. Physiology & Comfort Model Integration

Turn your manikin into a human simulator with a new software dimension that simulates complex human thermoregulation, comfort perception, and potential burn injury.

![]()

5D. End-User Product

The end user product gets its own dimension. Every stage of component and product evaluation needs to be focused on improving the user experience, whether safety, comfort, or value. Testing through the entire continuum gives your customer the confidence of ultimate product performance while keeping testing costs lower.

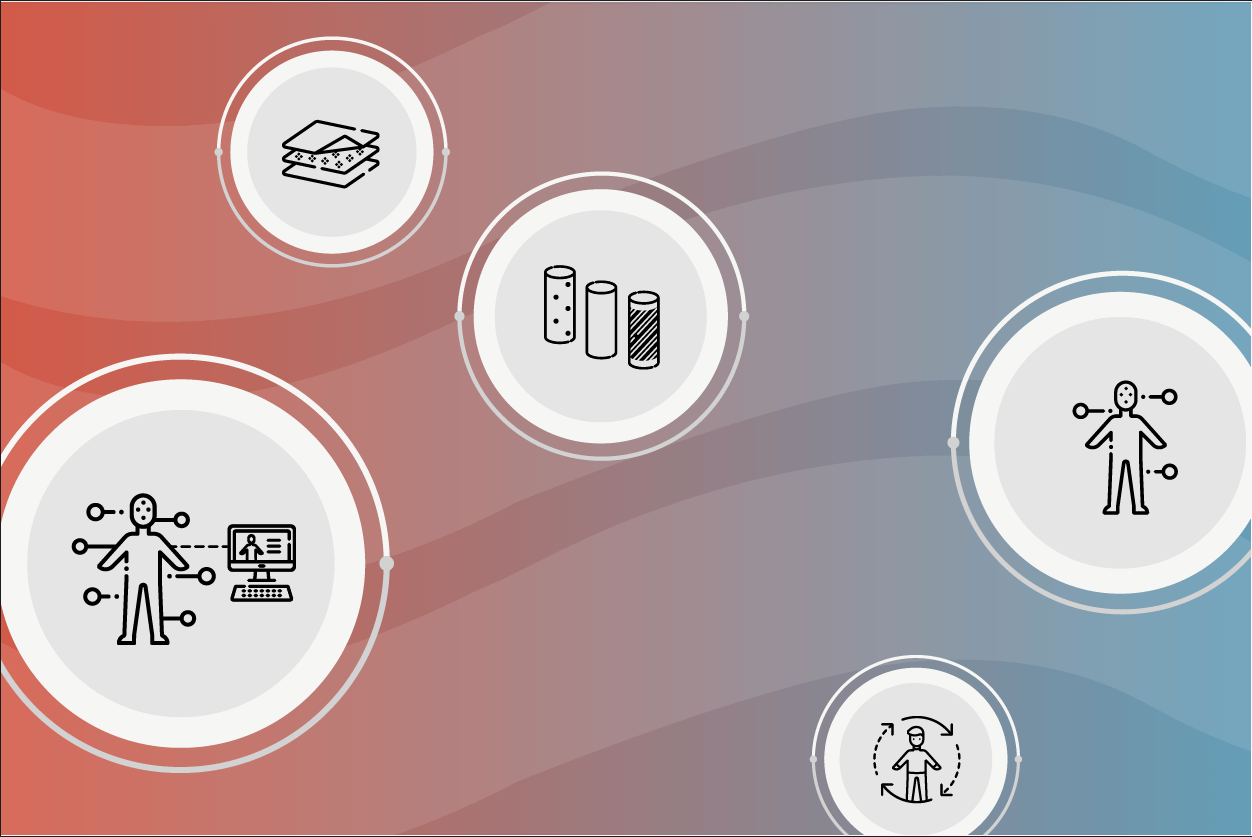

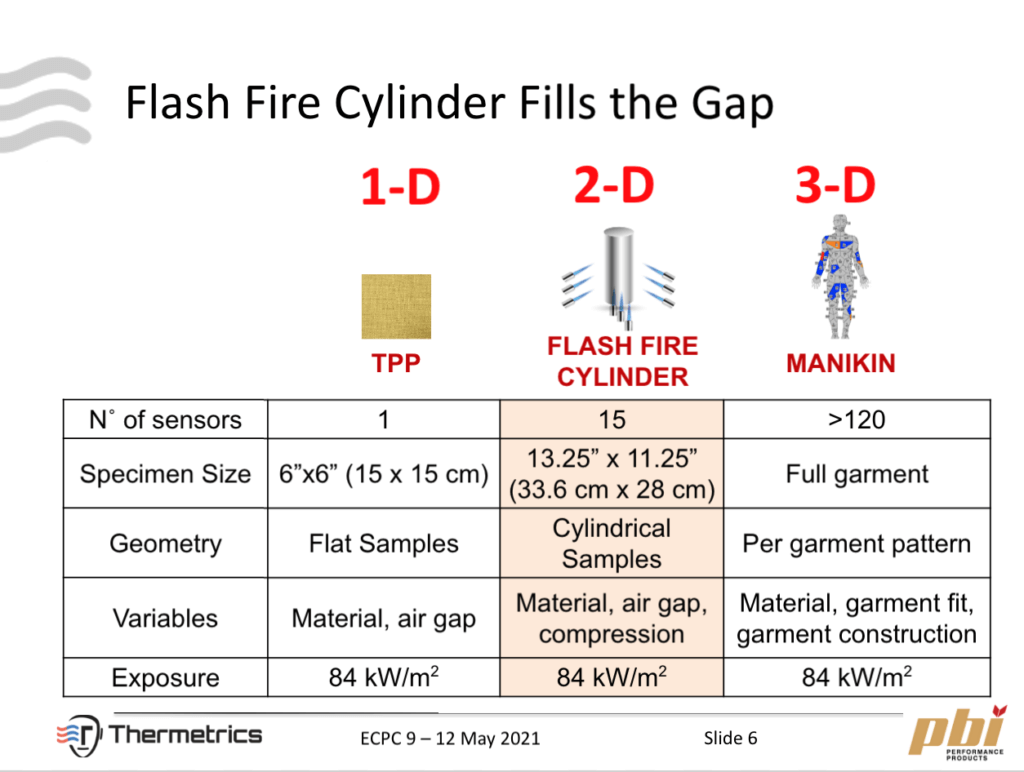

The Thermal Protection Testing Continuum

* Want a copy of this image for your reference, or to support discussions with your team? Download this Testing Continuum.

This testing continuum was designed to demystify the complex interactions between high heat sources, protective garments, and the brave individuals we aspire to protect. Ensuring that they receive the appropriate level of life and safety protection should not be left to chance.

The 5 phases of the Thermal Protection Testing Continuum are:

- Flat Sample Testing

- Cylinder Testing

- Flame Manikin Testing

- Burn Model Integration

- End-User Product

![]()

1D. Flat Sample Testing

Understand and characterize materials as flat samples and materials stack-ups. This can include intrinsic thermal properties, and also performance under compression or high-intensity heat exposure.

![]()

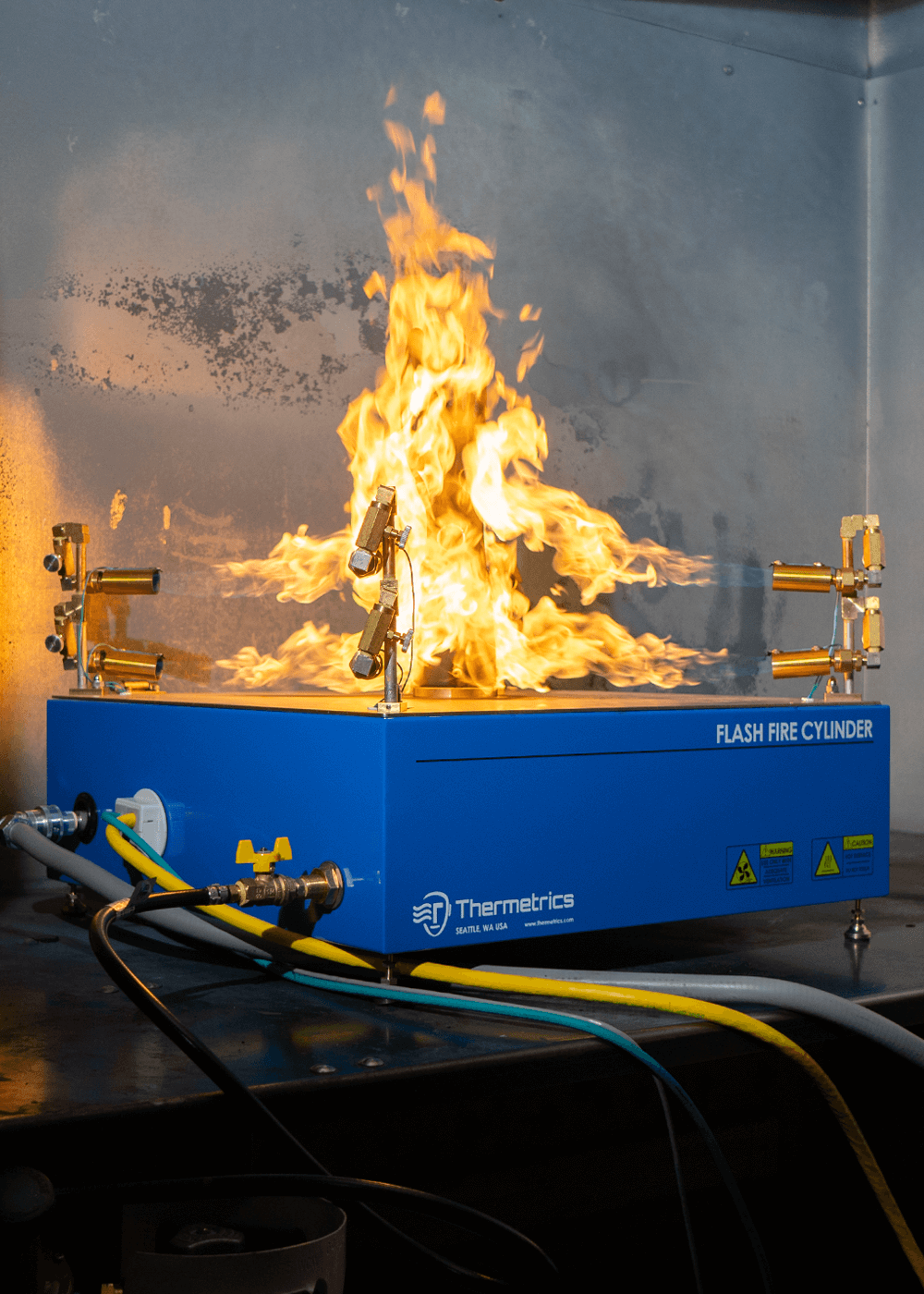

2D. Cylinder Testing

Capture effects of air gaps, vertical orientation, and fabric dimensional change or shrinkage.

![]()

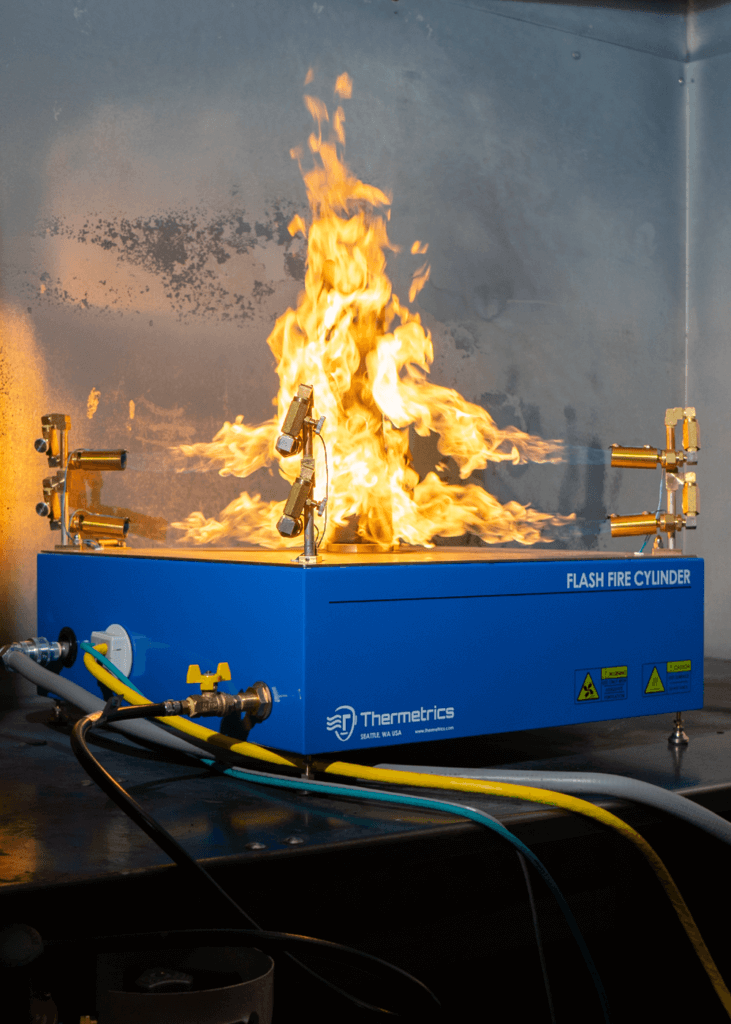

3D. Flame Manikin Testing

Evaluate finished goods on full- and partial-body manikin forms to understand the combined effects of materials, layers, and garment fit.

![]()

4D. Burn Model Integration

Estimate burn injury through a multi-node skin tissue model.

![]() 5D. End-User Product

5D. End-User Product

The end user product gets its own dimension. Every stage of component and product evaluation needs to be focused on improving the user experience, whether safety, comfort, or value. Testing through the entire continuum gives your customer the confidence of ultimate product performance while keeping testing costs lower.

In conclusion…

The thoroughness of these testing continuums delivers the certainty that you’re developing products that can withstand the world’s most extreme conditions and keep every end user safe, supported, and as comfortable as possible.

Wherever you want to be on the testing continuum, Thermetrics has a solution to help you get there. Contact us directly.